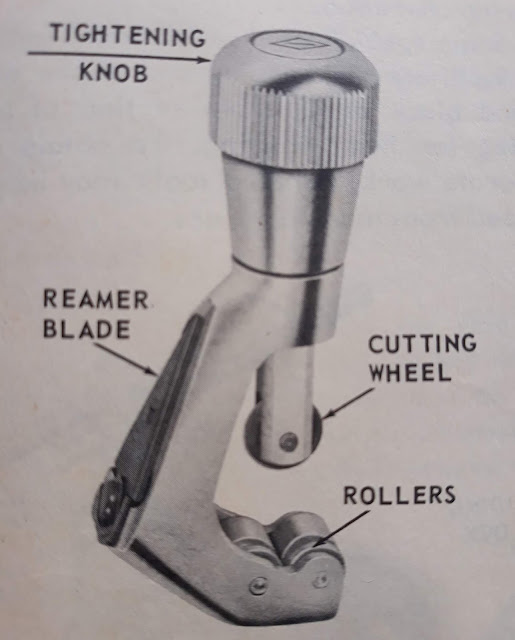

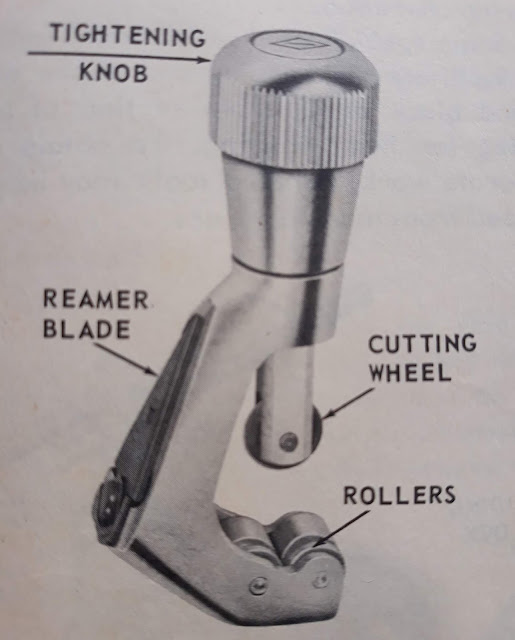

To cut tubing a hacksaw or a tube cutter may be used. The tube cutter should be used on the annealed copper tubing while the hacksaw is usually used for cutting hard copper tubing. Fig. 2-3 illustrates a wheel-type tube cutter. After the tubing |

Fig. 2-3. A copper tube cutter. This type of cutter is usually used on soft copper tubing. Note the attached reamer which is used to remove burrs from the inside of the tube after cutting. The grooves in the rollers allow the cutter to be used to remove a flare from a tube with little tubing waste. (Imperial-Eastman Corp.) |

has been cut, its ends must be scraped or reamed with a pointed tool to remove any sharp burrs at the end of the tubing. Most tube cutters have such a tool built into them for this purpose. If a saw is to be used, a wave set blade of 32 teeth per inch is preferable. It is important that no filings or chips of any kind be allowed to enter the tubing. In cutting tubing with a hacksaw, hold the tubing in such a manner that chips will not fall into the section that is to be used. Fig. 2-4 illustrates a sawing fixture.

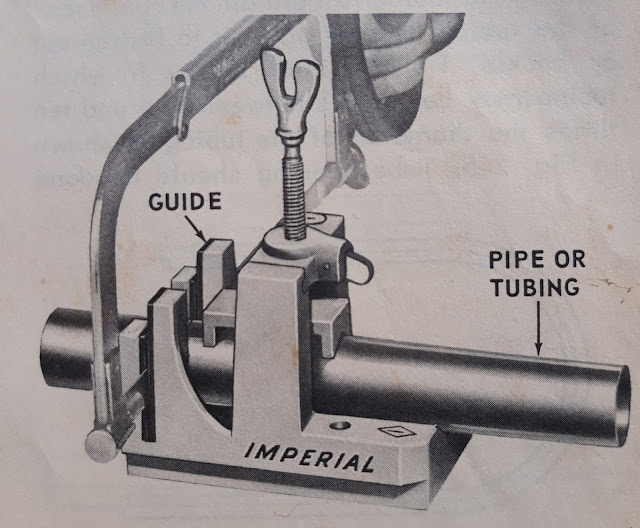

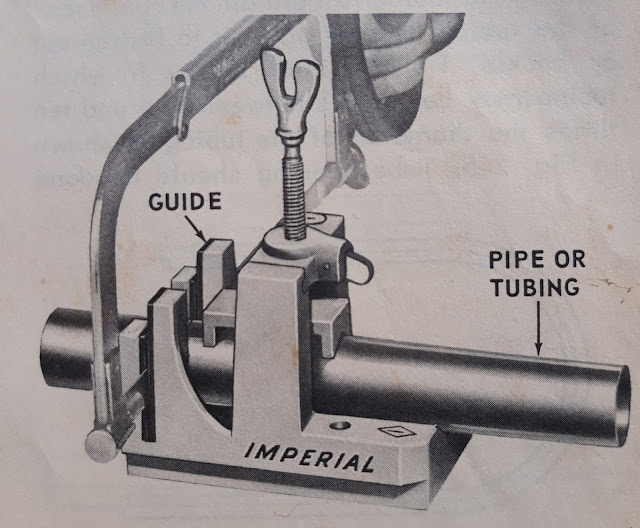

|

Fig. 2-4. A sawing fixture is used to insure square and accurate cuts when cutting tubing with the use of a hand hacksaw. This is the recommended method for cutting hard-drawn and steel tubing.

|

If soft tubing is used, pinching the tube eliminates the danger of chips entering the tubing that is not to be used. It also seals the tubing against moisture and protects it for further use. If hard copper tubing is being used, the tubing ends should be capped or plugged. To provide a full-wall thickness at the end of the tubing, many servicemen file the end of the tubing with a smooth or medium-cut mill file. The tubing should be straight to eliminate an off-center flare.