The tubing, at the bend, should not be reduced in cross-sectional area. Be very careful when bending the tubing to maintain the roundness of the tubing and do not allow it to flatten out or buckle. The minimum radius in which tubing may be bent is between five and ten times the diameter of the tubing as shown in Fig. 2-5. Tube bending should be done

quite slowly and carefully. It is always wise to bend the tubing into as large a radius as possible because this reduces the amount of flattening of the tubing to a minimum, and it is also easier to bend a large radius. Do not try to make the complete bend in one operation, but bend the tubing gradually so that it will not rupture by too sudden a stress. An inexpensive coil spring bending tool as illustrated in Fig. 2-6 may be easily carried in a kit. These are available in all sizes and are made for both external and internal use. The internal spring is for use near the ends of the tubing

or flared tubing, while the external is best used in the middle of long lengths of tubing. A 1/4 inch OD tube bending spring may be used as an internal spring for 1/2 inch OD tubing.

When the tubing is bent with a bending spring, it tends to bind to the tubing. It may be easily removed by twisting the spring to cause the external spring to expand or to cause the internal spring to contract. If a bend is to be made near a flare and an external spring is to be used, bend the tubing first. An internal spring can be used either before or after the flaring operation.

Some special tools which have been used to facilitate the bending operations are a round block or a short section of large piping for hand bending. To obtain very accurate work, bending tools may be purchased from manufacturers

|

| Fig. 2-5. The minimum safe bending radius for bending tubing. D is the diameter of the tube being bent. |

quite slowly and carefully. It is always wise to bend the tubing into as large a radius as possible because this reduces the amount of flattening of the tubing to a minimum, and it is also easier to bend a large radius. Do not try to make the complete bend in one operation, but bend the tubing gradually so that it will not rupture by too sudden a stress. An inexpensive coil spring bending tool as illustrated in Fig. 2-6 may be easily carried in a kit. These are available in all sizes and are made for both external and internal use. The internal spring is for use near the ends of the tubing

|

| Fig. 2-6. A tube bending spring which may be fitted either outside or inside a copper tube while bending the tube. The bending spring reduces the danger of a tube being flattened while being bent. |

or flared tubing, while the external is best used in the middle of long lengths of tubing. A 1/4 inch OD tube bending spring may be used as an internal spring for 1/2 inch OD tubing.

When the tubing is bent with a bending spring, it tends to bind to the tubing. It may be easily removed by twisting the spring to cause the external spring to expand or to cause the internal spring to contract. If a bend is to be made near a flare and an external spring is to be used, bend the tubing first. An internal spring can be used either before or after the flaring operation.

Some special tools which have been used to facilitate the bending operations are a round block or a short section of large piping for hand bending. To obtain very accurate work, bending tools may be purchased from manufacturers

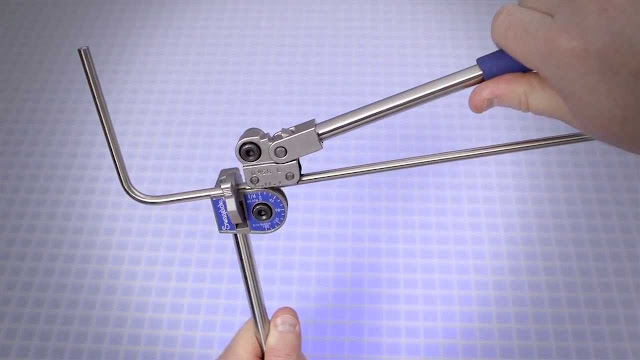

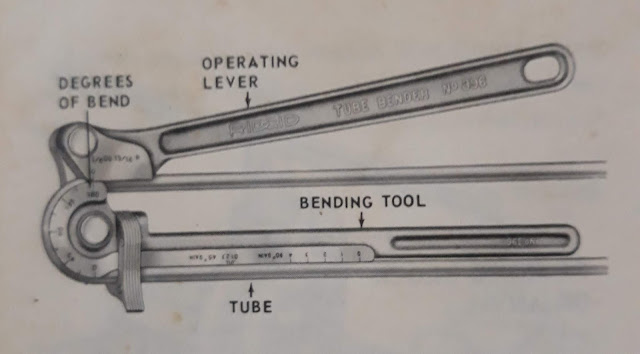

|

| Fig. 2-7. A tube bending tool designed to produce accurate bends and prevent buckling of the tube while bending. |

Fig. 2-7 shows a convenient tool used for bending tubing. A lever-type bender for accurate bending to within 1/32 in, for soft or hard tubing, is shown in Fig. 2-8. It can be purchased in six different sizes to

Fig. 2-9 shows some practice bends on the tubing.