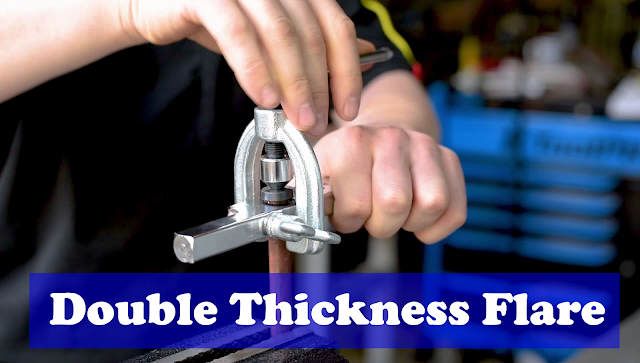

a double flare. The appear appearance of the double flare is shown in the final operation in this figure. Some flaring tools are fitted with adapters which makes it possible to form either single or double flares wi with the same tool. Fig. 2-15 shows such a tool.

|

| Fig. 2-15. A flaring tool which, with necessary adapters, is capable of producing either single or double flares. (lmperial-Eas tman Corp.) |

Fig. 2-16 shows the step-by-step procedure for making a double flare. Double-thickness flares are recommended for only the larger size tubing (5/16 in. and over) and are not easily formed on smaller tubing. The double flare makes a stronger joint than a single flare.

|

| Fig. 2-16. This shows the correct procedure for forming a double flare using the adapters with a combination single flare -double flare, flaring tool. |

_1.jpg)